industrial news

The difference between DIP led screen and SMD display screen

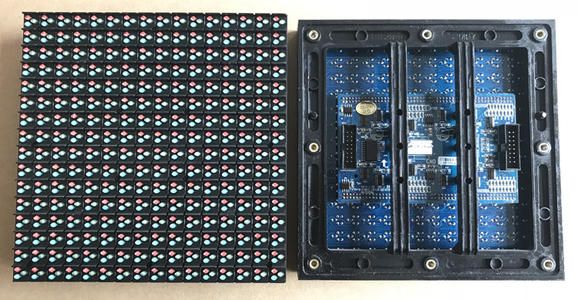

Now, as the primary component of LED electronic screen, LED lamp (light-emitting diode) has two packaging methods, namely DIP type and chip SMD type. Generally speaking, DIP LED screen is mainly used in outdoor display screen, while SMD LED is used in indoor LED large screen. What else is the difference between them?

The SMT LED is attached to the surface of the circuit board, suitable for SMT processing and reflow soldering. It can solve the problems such as brightness, viewing angle, flatness, reliability and consistency. Lighter PCB board and reflective layer material are used. After improvement, the heavier carbon steel pin of in-line LED is removed, which makes the display reflection layer need less epoxy resin. The intention is to reduce the scale and reduce the component 。 In this way, the appearance Mount LED can easily reduce the commodity weight by half, and finally make the use more perfect. SMD LED is usually used as the light source of indoor LED large screen, but with the breakthrough of technology, the brightness of SMD LED has been greatly improved, and the waterproof treatment can also be well treated. Therefore, the application of SMD LED in the field LED electronic screen is also increasing.